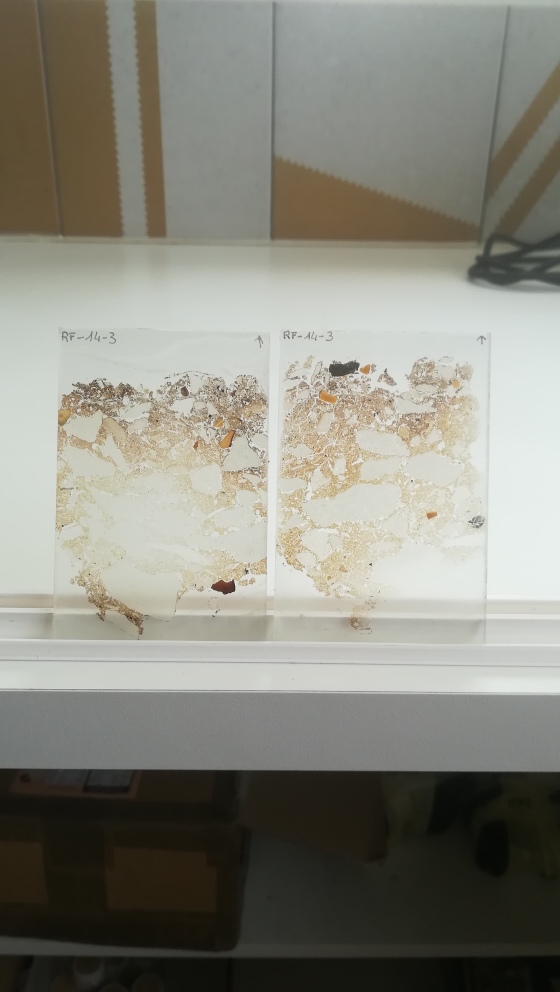

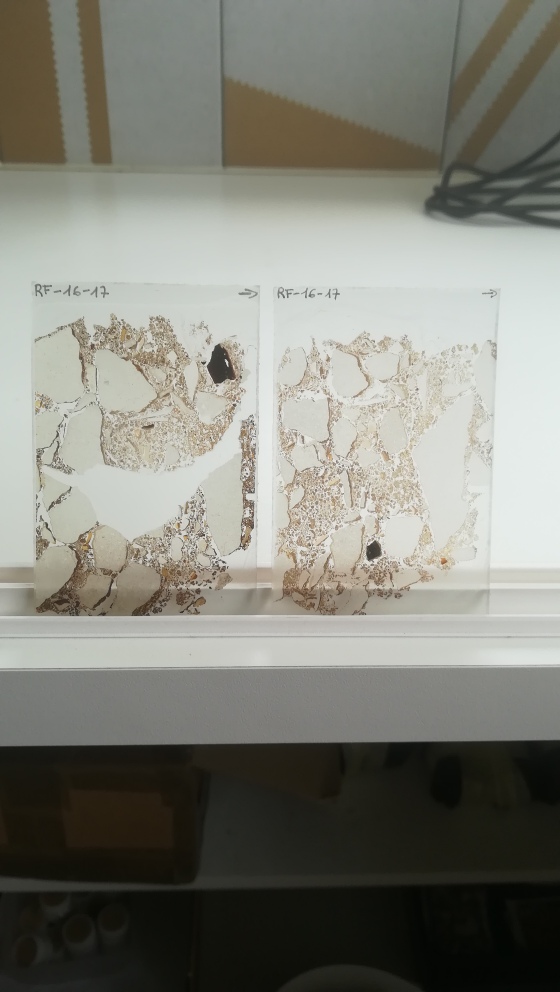

Terrascope has manufactured 8 thin sections from some cave deposits. The samples were already impregnated and the researcher provided us with one precut slab for each sample. As the slabs were thick, we could cut all of them in two pieces with our saw, to preserve a back-up in case the grinding did not go well at the first time. And we did well because we had to redo 3 slides on 8!

Five thin sections ground well on the first try and the back-up will be shipped to the researcher so she can keep them for archive or geochemical analysis for example. But for three other samples, the first grinding did not go as expected. Two samples did not grind evenly, one was loosing material from one side and the other in the middle. The second try on those two is much better. During the grinding of the third sample, a part of the sample simply detached from the glass, leaving big hole in the middle. Something probably caught in the grinding wheel and just ripped off the sample from the glass. Hopefully the second try was a success!

We hope the researcher will be happy with the slides. This project really shows the reality of thin section preparation. It is very hard to get perfect thin sections and having back-up samples is very important in case something goes wrong.If you need thin sections too, please contact us for a quote. And if you are interested in the thin section process, follow us on Instagram for more stories!